The Power of Predictive Analytics in Asset Performance Management

Key Takeaways

- Predictive analytics transforms asset management by drastically minimizing downtime and reducing long-term maintenance expenses.

- The intersection of sensors, historical data, and artificial intelligence equips organizations to truly understand and extend the life of their most critical assets.

- Case studies across industries highlight the rewarding results of transitioning to data-driven asset performance strategies operationally and financially.

- Collaboration between departments and investment in workforce development are essential for successful predictive analytics implementation.

- Continuous improvement and new technologies are redefining what’s possible in asset performance management at incredible speed.

- Recent industry news offers exciting examples of predictive analytics driving value in maintenance and reliability.

What Is Predictive Analytics in Asset Performance Management?

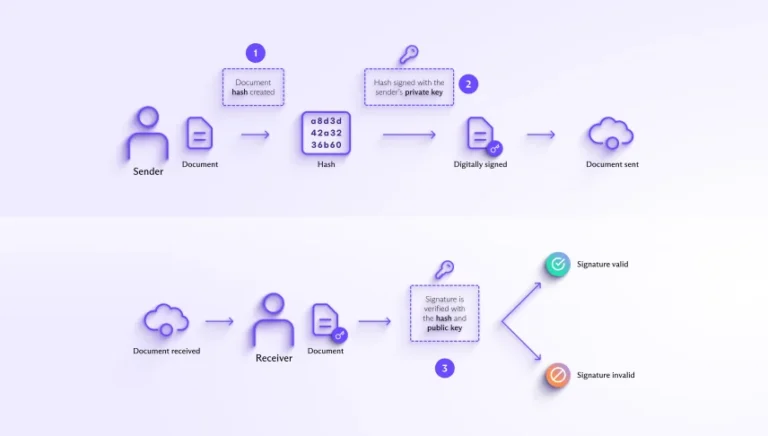

Predictive analytics in asset management represents a significant shift in how organizations approach the health and maintenance of their investments. Instead of simply reacting when a machine breaks down or adhering to strictly timed maintenance intervals, predictive analytics leverages real-time sensor data, historical performance records, and advanced statistical algorithms to forecast future equipment issues. This approach changes the narrative from “fix it when it fails” to “anticipate and mitigate before it breaks.” For many organizations, this is nothing short of a revolution in maintenance practices, delivering measurable uptime and cost-efficiency results. By integrating asset performance management software into their operational technology ecosystems, organizations can centralize and analyze enormous volumes of raw data from assets ranging from turbines and industrial robots to HVAC units and railway engines. This software uses artificial intelligence to scan for anomalies, uncover emerging trends, and deliver actionable prescriptive recommendations—all in real-time. As a result, engineers and technicians can address minor issues before they escalate, focusing resources wisely and minimizing business disruptions.

Core Components: How Predictive Analytics Works

- Sensor Integration: Modern assets come equipped with dozens, sometimes hundreds, of sensors. These sensors gather everything from vibration levels and rotational speed to operating temperatures, oil viscosity, and electrical currents. The ability to continuously capture and stream this data is foundational to predictive analytics.

- Data Aggregation: Rather than remaining in isolated pockets, all this information is gathered into centralized databases or cloud platforms. This unified approach enables teams to spot patterns and make comparisons that would be impossible otherwise, even across multiple sites or business units.

- Machine Learning Algorithms: Organizations can uncover subtle relationships among data points by employing sophisticated machine learning models. For example, a slight but persistent temperature spike in combination with increased vibration may signal that a bearing is about to fail. These patterns would easily escape traditional manual inspection routines.

- Actionable Insights: The end goal is more data and better decisions. Predictive analytics platforms are designed to interpret complex information and provide clear recommendations, such as “schedule a lubrication service in three days” or “plan for a gearbox replacement within the next maintenance window.”

According to a recent automation industry report, these technology pillars combine to drive a proactive maintenance culture that optimizes critical assets for safety, longevity, and return on investment.

Benefits That Go Beyond Cost Savings

While reducing maintenance budgets is an obvious draw, the move toward predictive analytics brings benefits that extend far deeper. One of the biggest advantages is the ability to maximize asset uptime, ensuring that production lines keep running and that costly equipment generates value for as many hours as possible. This approach also boosts worker safety by reducing the number of emergency repairs and rushed interventions, which are among the riskiest activities on any industrial site.

Furthermore, when repairs or servicing are performed based on genuine needs rather than fixed schedules, waste and the consumption of spare parts are reduced. This saves money and supports sustainability objectives by minimizing unnecessary manufacturing and shipment. McKinsey & Company has noted in their research that companies successfully implementing predictive maintenance strategies can cut costs by up to 30% and extend equipment life by as much as 20%, making the business case very compelling.

Examples: Real-World Transformations

The transformative power of predictive analytics can be seen in a diverse range of industries. For instance, a multinational automobile manufacturer recently used advanced monitoring to flag anomalous vibrations in a critical assembly line gearbox. Technicians were alerted early, intervened, and prevented an unplanned production halt that would have led to losses in the millions. Airlines, too, are embracing predictive models that analyze engine data mid-flight, identifying potential failures and prompting proactive maintenance once the plane lands. Utility companies operating vast wind farms deploy AI-based asset management systems to continuously track turbine data. This means that teams are dispatched only when maintenance is truly necessary, optimizing labor and reducing site visits, mainly in hard-to-reach locations. These real-world applications demonstrate that predictive analytics delivers much more than spreadsheets or traditional asset management routines ever could, helping organizations become more agile and resilient.

Key Challenges to Overcome

As promising as predictive analytics is, organizations often encounter obstacles on the journey to full-scale adoption. Legacy equipment may lack the embedded sensors required for robust monitoring, or departments might still work in silos, making integration with centralized platforms difficult. Another critical issue is cybersecurity, as more connected devices increase the attack surface for digital threats. Cultural hurdles can slow progress on the people’s side. Skilled technicians and operators many with decades of experience sometimes view automated analytics with skepticism. To counter this, change management and transparent communication are critical, as is demonstrating how predictive tools can complement, not replace, human expertise.

Steps to Implement Predictive Analytics Effectively

- Start by identifying a high-value asset or production line for your initial pilot. Success here builds support for organization-wide expansion.

- Invest in modern, industrial-grade sensors and structured data collection. Data quality directly influences the reliability of predictive models.

- Involving operational, maintenance, and IT teams from day one can break down internal barriers. Cross-functional alignment is key to smooth platform rollouts.

- Prioritize workforce education, offering training on data interpretation and the value of predictive maintenance insights.

- Use the results of your pilot phase to improve algorithms and showcase value, then scale up gradually to other assets and sites.

Many recent success stories confirm that organizations seeing the most significant returns treat predictive analytics as a technological and cultural evolution, fostering open collaboration and constant feedback.

The Evolving Future of Asset Performance Management

As technology continues to develop, the landscape of asset performance management is evolving in tandem. Artificial intelligence is becoming capable of processing data at a level of granularity unimaginable even a decade ago. Combined with the rapid growth of IoT connectivity, businesses now have access to insights on everything from minute component wear to weather-driven asset behavior. These advances mean that predictive analytics platforms could offer maintenance recommendations months in advance or automatically trigger supply chain actions for replacement parts before a breakdown occurs. Industries of all types, from healthcare (where medical equipment uptime can be a matter of life and death) to rail and utilities (where public reliability is paramount), are using these innovations to future-proof their operations against uncertainty.

Staying Ahead: Continuous Innovation and Industry Collaboration

The potential of predictive analytics in asset management isn’t just unlocked by technology, but through a spirit of ongoing improvement and shared expertise. Organizations that engage in cross-industry benchmarking participate in collaborative forums, remain attuned to new research and success stories, and gain a valuable edge. Best practices are constantly being redefined through data, intuition, and peer learning. With digital transformation accelerating everywhere, those who lead in predictive asset management will invest in people as much as their platforms cultivating skills, curiosity, and resilience that ensure long-term success and operational peace of mind.