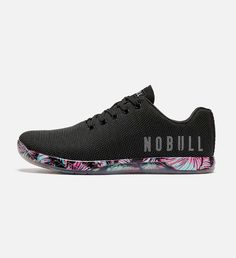

Where Are NOBULL Shoes Made? A Comprehensive Guide

NOBULL is a well-known brand in the fitness world, famous for its high-quality training shoes and apparel. Founded in 2015 by Marcus Wilson and Michael Schaeffer, NOBULL quickly gained a loyal following among athletes and fitness enthusiasts. One common question about this brand is, “Where are NOBULL shoes made?” In this article, we’ll explore the origins of NOBULL shoes, their manufacturing process, and what makes these shoes stand out.

The Origins of NOBULL Shoes:

NOBULL was created to provide athletes with simple, functional, and durable footwear and apparel. The founders, Marcus Wilson and Michael Schaeffer, were former Reebok employees with extensive experience in the athletic footwear industry. They noticed a gap in the market for straightforward, no-nonsense products that could withstand the rigours of intense training.

Design and Innovation:

Before diving into the specifics of where NOBULL shoes are made, it’s essential to understand the design and innovation behind them. NOBULL shoes are known for their minimalist design, focusing on functionality and durability. The shoes are designed to handle a variety of workouts, from weightlifting to running and everything in between.

Where Are NOBULL Shoes Made?

United States:

NOBULL shoes are designed in the United States, specifically at the company’s headquarters in Boston, Massachusetts. The design process starts here, where the team creates prototypes, tests different materials, and refines the shoe’s design to ensure it meets the brand’s standards for performance and durability.

China:

China is one of the primary locations for the production and final assembly of NOBULL shoes. There are several reasons why NOBULL chooses to manufacture its shoes in China:

- Expertise in Footwear Manufacturing: China has a well-established history of producing high-quality athletic footwear. The country has the necessary infrastructure, skilled labour, and technology to create durable and functional shoes.

- Cost-Effectiveness: Manufacturing in China is more cost-effective than in the United States. This cost advantage allows NOBULL to offer their products at competitive prices while maintaining high quality.

- Efficient Supply Chain: China has efficient supply chains for sourcing materials and components for footwear production. This efficiency helps reduce lead times and ensure a steady supply of products.

- Quality Control: Despite being manufactured overseas, NOBULL maintains strict quality control standards. The company works closely with its manufacturing partners to ensure that every pair of shoes meets their high standards.

Vietnam:

Vietnam is another key location for the production and final assembly of NOBULL shoes. The reasons for choosing Vietnam are similar to those for China:

- Expertise in Footwear Manufacturing: Vietnam has a well-established footwear manufacturing industry with skilled labour and advanced technology.

- Cost-Effectiveness: Manufacturing in Vietnam is also cost-effective, helping NOBULL keep their products competitively priced.

- Efficient Supply Chain: Vietnam has a strong supply chain network for materials and components needed for footwear production.

- Quality Control: NOBULL ensures that its manufacturing partners in Vietnam adhere to strict quality control standards to maintain the high quality of their shoes.

Key Features of NOBULL Shoes:

- Durable Materials: NOBULL shoes are made from SuperFabric, a highly durable and breathable material. This fabric is resistant to abrasions, making the boots last longer, even with heavy use.

- Versatile Performance: The design of NOBULL shoes ensures they perform well in various workouts. Whether lifting weights, doing CrossFit, or running, these shoes provide the support and stability you need and they are also sold in stores and easily available.

- Minimalist Design: NOBULL shoes have a sleek, simple design without unnecessary frills. This minimalist approach looks good and ensures that the boots are functional and practical.

- Comfort and Fit: The shoes are designed to be comfortable, with features like a breathable upper and a flexible sole that adapts to the shape of your foot.

The Manufacturing Process:

To understand the journey of a NOBULL shoe, let’s go through the manufacturing process step-by-step:

Design and Development:

The design process starts at NOBULL’s headquarters in Boston. The design team creates prototypes, tests different materials, and refines the shoe’s design to ensure it meets the brand’s standards for performance and durability.

Material Sourcing:

NOBULL sources high-quality materials from various suppliers. This includes SuperFabric for the shoe’s upper part, rubber for the soles, and other components that ensure the shoe’s performance and durability.

Cutting and Sewing:

The materials are shipped to manufacturing facilities in China and Vietnam, where they are cut and sewn together. This stage involves skilled labour to ensure the pieces fit together perfectly and the shoe’s structure is sound.

Assembling the Sole

The sole, made from durable rubber and other materials, is attached to the shoe’s upper part. This step involves strong adhesives and precise stitching to ensure the shoe’s integrity.

Quality Control:

Before the shoes are shipped, they undergo rigorous quality control checks. Each pair is inspected for defects and tested to ensure they meet NOBULL’s high standards for performance and durability.

Packaging and Shipping:

Once the shoes pass quality control, they are packaged and prepared for shipping. They are then distributed to retailers and customers around the world.

Also Read: Where Are Hotter Shoes Made?

Sustainability and Ethical Practices:

NOBULL is committed to sustainable and ethical practices in its manufacturing process. Here are some steps they are taking:

Sustainable Materials:

To minimize their environmental impact, NOBULL is exploring sustainable materials, including recycled and eco-friendly alternatives.

Ethical Manufacturing:

The company ensures that its manufacturing partners adhere to ethical labour practices, including fair wages, safe working conditions, and no child labour. Regular audits are conducted to ensure compliance with these standards.

Reducing Carbon Footprint:

NOBULL is focused on reducing its carbon footprint by optimizing its supply chain to reduce emissions and exploring renewable energy sources for its facilities.

The Popularity of NOBULL Shoes:

NOBULL shoes have gained a significant following in the fitness community. Their popularity can be attributed to several factors:

High-Quality Products:

NOBULL’s commitment to quality is evident in their products. Athletes and fitness enthusiasts appreciate the durability and performance of NOBULL shoes.

Community Engagement:

NOBULL has built a strong community of loyal customers. They engage with their audience through social media, events, and athlete collaborations. This sense of community helps foster brand loyalty.

Innovative Marketing:

The company uses innovative marketing strategies to reach their target audience. This includes partnering with influencers, creating engaging content, and leveraging social media platforms.

Positive Reviews:

Positive reviews and word-of-mouth recommendations have also significantly impacted NOBULL’s success. Customers who are satisfied with their purchase will likely recommend the brand to others.

Also Read: Where Are Le Sansa Shoes Made?

Frequently Asked Questions

Conclusion:

NOBULL shoes are designed in the USA but are primarily manufactured and assembled in China and Vietnam. This approach leverages these countries’ expertise, cost-effectiveness, and efficient supply chains, ensuring that NOBULL shoes maintain high quality and performance. The company’s commitment to sustainability and ethical practices further enhances its reputation as a leading brand in the fitness world.

Whether you’re you’re a professional athlete or enjoy regular workouts, NOBULL shoes offer the needed performance and reliability. With a focus on innovation and community engagement, NOBULL is a brand that stands out in the fitness world. So, the next time you lace up your NOBULL shoes, you can appreciate the craftsmanship and dedication to making each pair.